Motor Selection Guide: Comparing DC, Brushless, and Stepper Motors

Motor Selection Guide: Comparing DC, Brushless, and Stepper Motors

Choosing the right motor is essential for achieving the desired performance, precision, and reliability in automation and mechanical systems. This guide compares three major types of motors commonly used in gearmotor applications: DC Gear Motors, Brushless Gear Motors, and Stepper Motors (including Hybrid Stepper Motors). Each offers distinct advantages for specific application needs.

1. DC Gear Motor

Vpeak DC Gear Motor

DC gear motors are widely used for their high speed, strong torque, and ease of control. They are ideal for applications requiring continuous rotation, variable speed, and straightforward operation.

Advantages:

– High speed and strong torque

– Simple wiring and control

– Cost-effective and widely available

– Can provide position feedback and improved control when paired with an encoder

– Most affordable solution for many automation needs

– Lightweight and compact, making integration easier

– With our unique upgraded internal techniques, the lifespan of Vpeak DC motors is significantly extended compared to traditional models

– Excellent option for budget-conscious projects without sacrificing performance

Considerations:

– Without feedback, their position accuracy depends on external calibration or estimation.

– Brushed versions may require occasional maintenance due to brush wear

Although traditionally not as precise as stepper motors, DC motors with encoders can still achieve a reasonable level of position control.

2. Brushless Gear Motor (BLDC)

Vpeak BLDC Gear Motor

Brushless DC motors are more efficient and durable than brushed motors. They operate without physical brushes, which reduces wear and extends lifespan, making them suitable for higher-end or continuous-duty systems.

Advantages:

– High efficiency and power density

– No brush wear — longer lifespan

– Smooth operation and reduced noise

– Suitable for continuous-duty applications

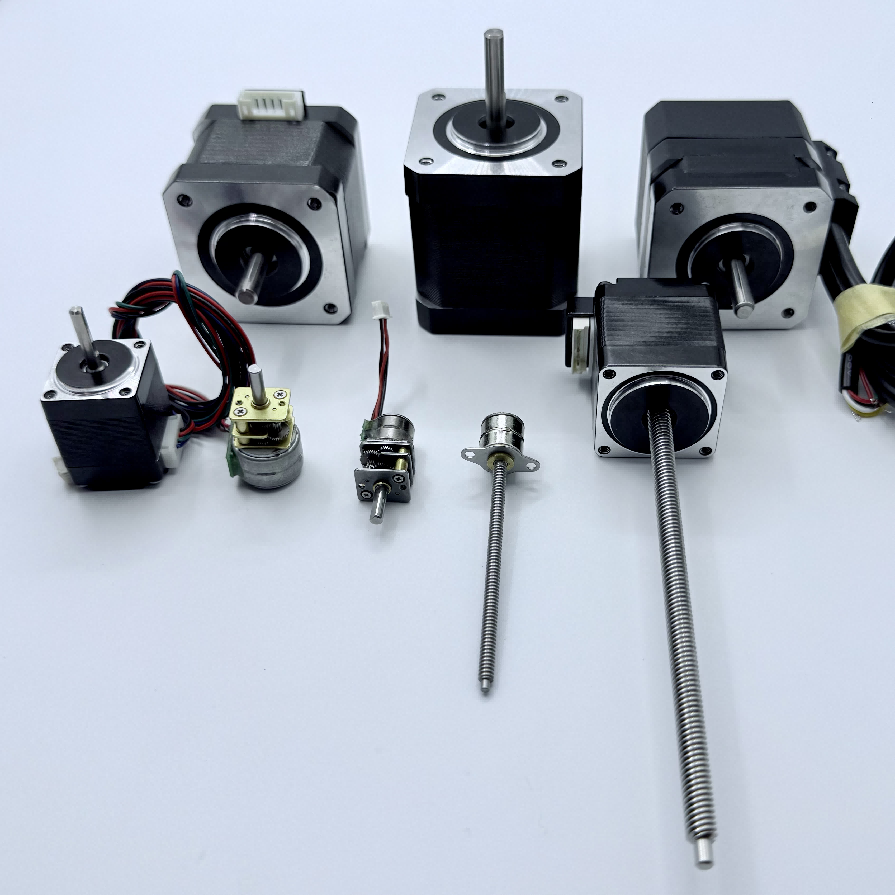

3. Stepper Motor & Hybrid Stepper Motor

Vpeak Stepper Motor & Hybrid Stepper Motor

Stepper motors, including hybrid stepper motors, excel in precise angular control. Unlike DC motors, they move in fixed step increments, making them ideal for applications needing accurate, repeatable motion.

Advantages:

– Precise position and angle control

– Open-loop control often sufficient (no encoder needed)

– High torque at low speeds

– Hybrid models offer enhanced precision and smoother motion

Typical Uses:

– 3D printers

– CNC machines

– Automated positioning systems

Stepper motors are perfect for systems that require precise, incremental movement without complex feedback systems.

Conclusion

Each motor type has specific strengths, making it suitable for different applications:

– DC Gear Motors are powerful, affordable, and flexible — especially with encoder-based feedback for moderate precision. Our unique internal improvements ensure enhanced durability compared to traditional DC motors.

– Brushless Motors provide high performance with long service life — ideal for demanding, continuous use.

– Stepper and Hybrid Stepper Motors are unmatched in delivering precise angular control — essential for automated and precision-driven systems.

Choosing the right motor depends on your application’s torque, speed, accuracy, and cost priorities.