Choosing Between Spur, Worm, and Planetary Gearboxes: A Practical Comparison

When selecting a gearbox for industrial or automation applications, it’s important to understand the advantages of different gear types. Spur, Worm, and Planetary gearboxes each offer unique benefits in terms of efficiency, cost, space, and functionality. This comparison outlines key features to help guide your decision-making process.

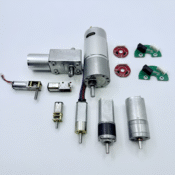

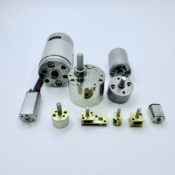

1. Spur Gearbox

Vpeak Spur Gearbox

Spur gearboxes use straight-cut gears and are among the most common gear types. They are efficient and reliable for applications requiring parallel shaft alignment.

Advantages:

– Good transmission efficiency

– Simple structure and easy maintenance

– Cost-effective solution for general applications

– To achieve high durability, the standard brass or bronze plate can be replaced with steel plates or gears

Gearbox with Steel Plates

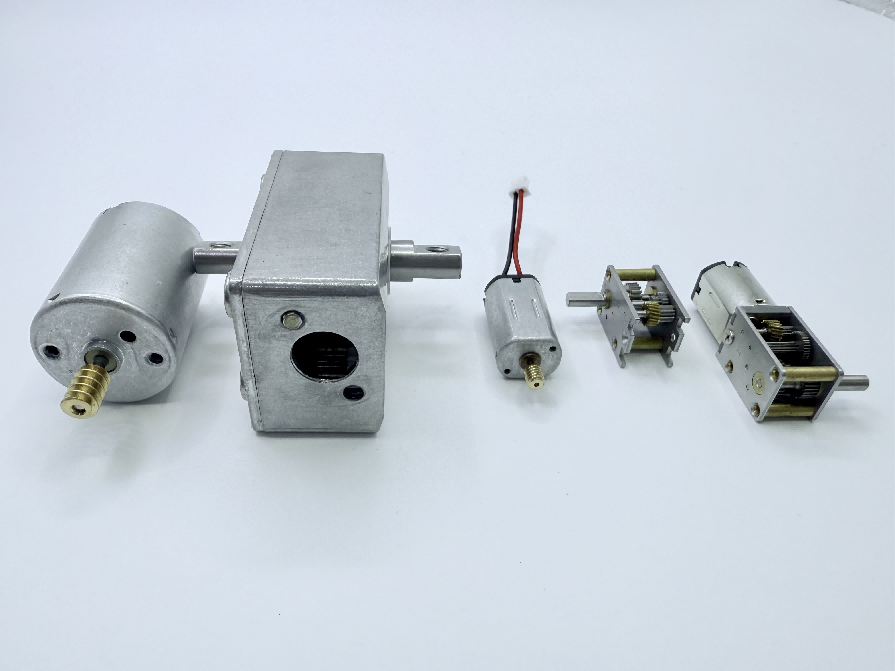

2. Worm Gearbox

Vpeak Worm Gearbox

Perpendicular Transmission

Worm gearboxes operate with a worm screw meshing with a worm wheel, providing smooth, quiet transmission and the ability to transmit motion at a 90-degree angle.

Advantages:

– Enables right-angle transmission

– Quiet and compact

– Built-in self-locking capability for enhanced safety

– To improve durability, replacing brass components with steel is recommended for heavy-duty use

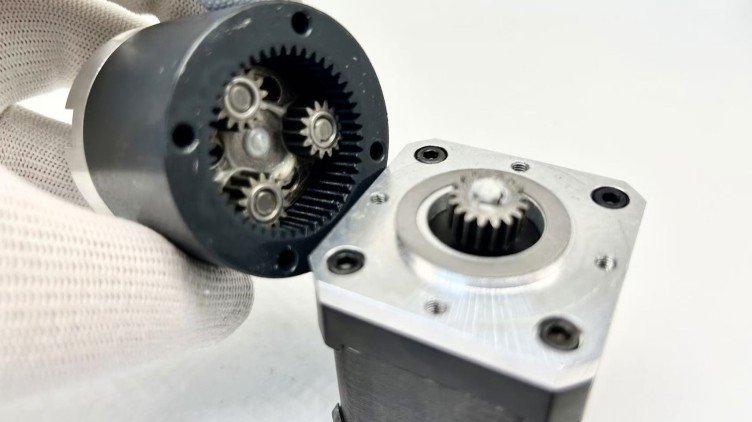

3. Planetary Gearbox

Vpeak Planetary Gearbox

Planetary gearboxes feature a sun gear surrounded by multiple planet gears enclosed in a ring gear. This design offers balanced load distribution and high torque in a compact footprint.

Advantages:

– Highest transmission efficiency among the three types

– Excellent torque density in compact form

– High precision and smooth motion

– Long service life with minimal maintenance

– Ideal for demanding or high-performance systems

Vpeak Nema 17 with Planetary Gearbox

Precision with Minimal Transmission Error

Efficiency & Feature Comparison

| Feature | Planetary Gearbox | Spur Gearbox | Worm Gearbox |

| Transmission Efficiency | Excellent | Good | Good |

| Torque Capacity | Excellent | Good | Good |

| Size-to-Power Ratio | Excellent | Good | Good |

| Self-Locking | On high ratio | On high ratio | Yes |

| Right-Angle Output | No | Can be 180’ | Yes |

| Noise Level | Low | Medium | Medium |

| Durability (Upgradable) | Excellent | Good | Good |

| Cost | High | Low to Medium | Low to Medium |

Conclusion

Each gearbox type has its own strengths, making them suitable for different use cases:

– Spur gearboxes offer simplicity, cost-efficiency, and solid performance for general applications.

– Worm gearboxes provide quiet operation, compact design, and self-locking ability—perfect for applications needing 90-degree drive.

– Planetary gearboxes deliver the highest efficiency, torque, and precision, suitable for high-demand or precision-driven environments.

Choosing the right gearbox depends on your application’s efficiency requirements, spatial constraints, and operational priorities.

When selecting a gearbox for industrial or automation applications, it’s important to understand the advantages of different gear types. Spur, Worm, and Planetary gearboxes each offer unique benefits in terms of efficiency, cost, space, and functionality. This comparison outlines key features to help guide your decision-making process.

1. Spur Gearbox

Vpeak Spur Gearbox

Spur gearboxes use straight-cut gears and are among the most common gear types. They are efficient and reliable for applications requiring parallel shaft alignment.

Advantages:

– Good transmission efficiency

– Simple structure and easy maintenance

– Cost-effective solution for general applications

– To achieve high durability, the standard brass or bronze plate can be replaced with steel plates or gears

Gearbox with Steel Plates

2. Worm Gearbox

Vpeak Worm Gearbox

Perpendicular Transmission

Worm gearboxes operate with a worm screw meshing with a worm wheel, providing smooth, quiet transmission and the ability to transmit motion at a 90-degree angle.

Advantages:

– Enables right-angle transmission

– Quiet and compact

– Built-in self-locking capability for enhanced safety

– To improve durability, replacing brass components with steel is recommended for heavy-duty use

3. Planetary Gearbox

Vpeak Planetary Gearbox

Planetary gearboxes feature a sun gear surrounded by multiple planet gears enclosed in a ring gear. This design offers balanced load distribution and high torque in a compact footprint.

Advantages:

– Highest transmission efficiency among the three types

– Excellent torque density in compact form

– High precision and smooth motion

– Long service life with minimal maintenance

– Ideal for demanding or high-performance systems

Vpeak Nema 17 with Planetary Gearbox

Precision with Minimal Transmission Error

Efficiency & Feature Comparison

| Feature | Planetary Gearbox | Spur Gearbox | Worm Gearbox |

| Transmission Efficiency | Excellent | Good | Good |

| Torque Capacity | Excellent | Good | Good |

| Size-to-Power Ratio | Excellent | Good | Good |

| Self-Locking | On high ratio | On high ratio | Yes |

| Right-Angle Output | No | Can be 180’ | Yes |

| Noise Level | Low | Medium | Medium |

| Durability (Upgradable) | Excellent | Good | Good |

| Cost | High | Low to Medium | Low to Medium |

Conclusion

Each gearbox type has its own strengths, making them suitable for different use cases:

– Spur gearboxes offer simplicity, cost-efficiency, and solid performance for general applications.

– Worm gearboxes provide quiet operation, compact design, and self-locking ability—perfect for applications needing 90-degree drive.

– Planetary gearboxes deliver the highest efficiency, torque, and precision, suitable for high-demand or precision-driven environments.

Choosing the right gearbox depends on your application’s efficiency requirements, spatial constraints, and operational priorities.